Kylchap Steam Locomotive Exhaust System

Thus the name kylchap for this design.

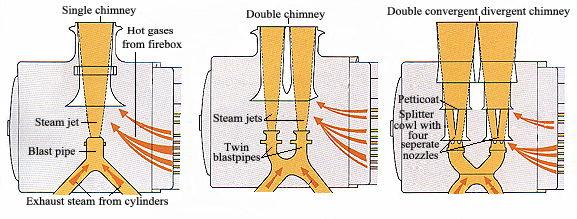

Kylchap steam locomotive exhaust system. The development of locomotive exhausts took a leap forward in 1926 when andré chapelon developed his kylchap exhaust which incorporated a. Steam locomotive exhaust drawings. Patents 622 123 626 276 8 21 1926 copies available from the i n p i. For a typical locomotive m is around 2 varies with degree of superheat grate area.

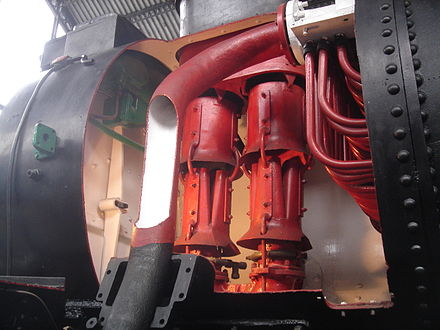

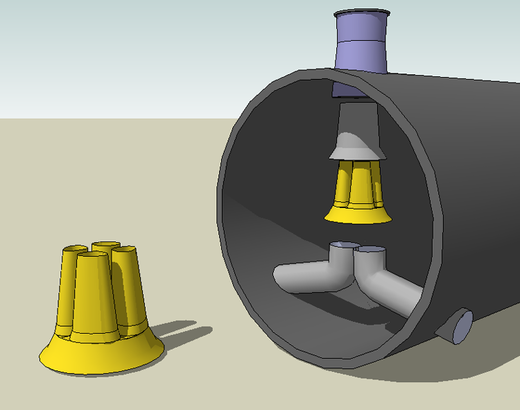

I had come to the conclusion that the combined input area of the various bellmouths in a kylchap system would be greater than for any other common exhaust system. This drawing shows an early kylchap exhaust. It usually consists of the blastpipe or first stage nozzle smokebox and chimney although later designs also include second and third stage nozzles. The whole steam system was subjected to chapelon s careful attention to optimize efficiency.

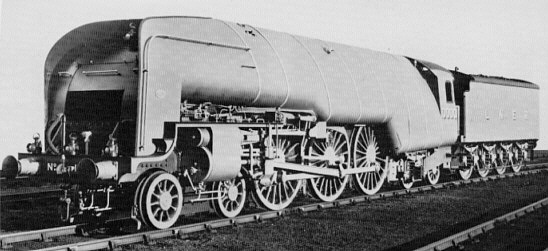

To ensure the best efficiency chapelon used the first ever triple kylchap exhaust to evenly cater for each of the three cylinders. Unfortunately the larger a steam locomotive gets the less height is available for the exhaust system. The kylchap steam locomotive exhaust system was designed and patented by french steam engineer andré chapelon using a second stage nozzle designed by the finnish engineer kyösti kylälä and known as the kylälä spreader. The kylchap steam locomotive steam locomotive exhaust system was designed and patented by the famous french steam engineer andré chapelon using a second stage nozzle designed by the finnish engineer kyösti kylälä and known as the kylälä spreader.

The kylchap exhaust consists of four stacked nozzles the first exhaust nozzle uk. The kylchap steam locomotive exhaust system was designed and patented by french steam engineer andré chapelon using a second stage nozzle designed by the finnish engineer kyösti kylälä and known as the kylälä spreader. Thus it was to the advantage of the railroad and the locomotive designer to optimize the exhaust system. Updated 23 june 2012.

And pressure ratio draught exhaust back pressure and area ratio blast pipe choke. This caused back pressure in the cylinders which represented a power loss and an inefficiency. In steam s last years this was a little known but important element of the high horsepower superpower movement in steam design. Basically it is made by stacking of four different nozzles the first one blowing exhaust steam only and called primary nozzle a chapelon designed item of a very particular shape generating as few as possible back pressure dividing the steam flow into four jets.

Basically the taller an exhaust system can be the better it functions. Thus the name kylchap for this design. The steam locomotive exhaust system consists of those parts of a steam locomotive which together discharge exhaust steam from the cylinders in order to increase the draught through the fire. Thus the name kylchap for this design.